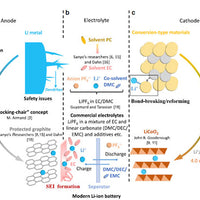

Power battery is influenced by the environment temperature is more significant, the characteristics of energy and power of lithium-ion power battery will appear serious attenuation, restrict lithium battery low-temperature characteristics of the key factors mainly include low-temperature electrolyte ion conductivity, negative particles of SEI film on the surface of electrochemical reaction rate, low electrical conductivity, battery, and lithium-ion diffusion coefficient in the anode graphite material grains. To improve the low-temperature performance of a power battery in a low-temperature environment, it is necessary to heat it.

Self-heating function of lithium-ion battery

Often we need the electrolyte and the electrode to make corresponding adjustments, such as high cost and performance of sacrifice at the expense of improving the low-temperature performance of the Li-ion battery, recently researchers have put forward a new train of thought, not replacement ratio of low-temperature electrolyte and electrode, from cell structure, only by inside the battery plate inserted between polymer coated with an insulating layer of Ni foil, realize the function of lithium-ion batteries from heating, can the lithium-ion battery within 30 s from heated to 0 ℃ to 30 ℃, and this process consumes only 5.5% of battery power.

Currently, there are two main ways to heat a battery: external heating and internal heating. External heating is mainly realized utilizing heat conduction or thermal convection, and the battery is heated externally by PTC material or heating film. However, this method is not evenly heated and its heating efficiency is low. Internal heating directly generates heat in the battery, so the heating efficiency is higher and the heating is more uniform.

Due to the low thermal conductivity of the lithium-ion battery structure, when the temperature of the battery surface rises from -20℃ to 0℃, the temperature of the Ni foil in the middle of the battery reaches about 30℃, forming a large temperature gradient between the battery interior and the surface. This temperature difference will lead to the difference in the discharge rate of different battery electrodes. Due to the existence of a large temperature gradient, the self-healing process has a bad effect on the performance of the battery, and also leads to the large heating energy consumption of the lithium battery.

Power battery self-heating technology

Both ultra-low temperature and low temperature will greatly reduce the activity of the power battery, and the power battery will show unstable working conditions, worse discharge characteristics, capacity, and life attenuation, which will lead to a significant decline in the driving range of the vehicle and the power performance of the vehicle, and significantly extend the charging time. A technology developed in China enables lithium-ion battery technology to self-heat, the battery system can be applied to lower temperatures, 30℃ below zero based on the method of self-healing in a few seconds can make the battery temperature rise above 0℃, thus activating the normal application of power battery.

Power battery self-heating method steps:

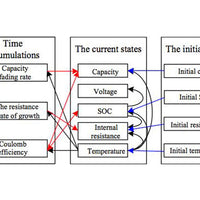

- the periodic receiving temperature sensor of the battery management system BMS 1 and temperature sensor 2.

- the battery management system BMS detects whether the current temperature meets the closing condition of the relay.

- Battery management system BMS controls DC/DC converter 1 to convert the output voltage of the first battery into the charging voltage of the second battery, and DC/DC converter 2 to convert the output voltage of the second battery into the charging voltage of the first battery.

The comparison of different heating methods shows that the external heating method relies on the external heating source to heat the power battery through heat conduction, which has a complex structure, high energy consumption, uneven heating temperature distribution, and slow heating speed. The internal heating method relies on the impedance of the power battery to generate heat, which has the advantages of fast and uniform heating. The ac heating method has the advantages of low energy consumption, uniform temperature distribution, low cost, and high heating efficiency.

Through the test, the self-heating system can realize the self-heating task of electric vehicle power battery under a low-temperature environment. As an important part of new energy vehicles, the performance of batteries determines the performance of vehicles to a large extent, and the different environment also has a certain impact on the use of batteries. At present, Impress NCM lithium battery also has the characteristics of low-temperature resistance. With the development of technology, the low-temperature bottleneck of new energy vehicles will be gradually solved.

0 comments