Internal resistance(IR) is one of the important indicators to evaluate the performance of lithium batteries. The test of internal resistance includes AC internal resistance and DC internal resistance. For single-cell batteries, AC internal resistance is generally used for evaluation, which is usually called ohmic internal resistance.

However, for large battery pack applications, such as power supply systems for electric vehicles, due to the limitations of test equipment and other aspects, it is not possible or convenient to directly test the AC internal resistance, and the characteristics of the battery pack are generally evaluated by DC internal resistance. In practical applications, DC internal resistance is also mostly used to evaluate the health of the battery, to make life prediction, and to estimate system SOC, output/input capacity, etc. In production, it can be used to detect phenomena such as faulty cells such as micro-short circuits.

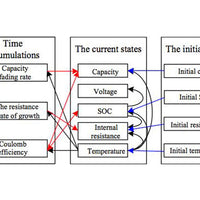

The principle of DC internal resistance testing is to calculate the DC internal resistance of a battery by applying a high current (charging or discharging) to the battery or battery pack for a short period, before the battery has reached full internal polarization, based on the voltage change of the battery before and after the applied current and the applied current. Four parameters must be selected to test the DC internal resistance: current (or adopted multiplier), pulse time, state of charge (SOC), and test environment temperature. The variation of these parameters has a large impact on the DC internal resistance.

DC internal resistance not only includes the ohmic internal resistance part of the battery pack (AC internal resistance part) but also partly includes some polarization resistance of the battery pack. And the polarization of the battery is more influenced by the current, time, etc.

At present, the commonly used DC internal resistance test methods are the following three:

(1) HPPC test method in the U.S. FreedomCAR Battery Test Manual: the test duration is 10s, the applied discharge current is 5C or higher, and the charging current is 0.75 of the discharge current. the specific current selection is based on the characteristics of the battery to develop.

(2) Japan JEVSD713 2003 test method, originally mainly for Ni/MH batteries, later also applied to lithium-ion batteries, first establish the current and voltage characteristic curve of the battery under 0~100% SOC, respectively charge or discharge the battery under the set SOC with the current of 1C, 2C, 5C, 10C, the charging or discharging time is 10s, and calculate the DC internal resistance of the battery.

(3) The test method proposed in the "High Power Lithium-ion Power Battery Performance Test Specification for HEV" of China's "863" Electric Vehicle Major Project, the test duration is 5s, the charging test current is 3C, and the discharging test current is 9C.

Determination of internal resistance of lithium-ion battery

in Technology

0 comments