In recent years, there has been a boom in small, battery-powered devices such as tablets, hand-held games consoles, video players, and digital photo frames. Generally, these devices are powered by rechargeable Li-ion batteries. Some common charging solutions include a wall adapter type charger and a Universal Serial Bus (USB) type charger. While these chargers are a low-cost solution for charging lithium-ion batteries, they all have a common flaw: they rely on the main power source to work. This dependence on mains power adds to consumers' electricity bills, as well as greenhouse gas emissions. And because of their dependence on the main power source, these charging solutions are less portable. Solar chargers that use solar panels to capture natural light energy may be the ideal way to extend battery life in an environmentally friendly way. Another benefit of the solar charger is that it provides a removable charging solution.

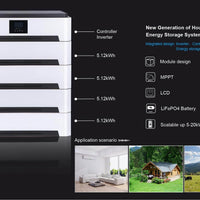

We will describe some important considerations in developing solar charging solutions. An important reason to consider these factors is that a solar panel can be a high-output impedance source with varying voltage and current depending on the light environment. The wall power adapter or USB power supply is a low output impedance power supply with predefined output voltage and current. Factors to focus on in the solar charging solution we will discuss include maximum power point tracking (MPPT), reverse leakage protection, charging termination techniques, and solar panel crash protection.

Maximum power point tracking

A maximum power point (MPP) is the working area of a solar cell that can obtain maximum power [1]. The graph in Figure 1 shows this region. The graph shows the comparison of the typical output current and output power with the voltage curve of the MPP two-node solar panel. The MPP on the curve is obvious because it corresponds to the voltage and current output of the solar panel at its maximum power. MPP is related to ambient temperature and light, so it changes over time. This suggests that chargers using solar power must have circuits to keep track of Mpp as environmental conditions change. MppT methods range from simple open-loop techniques (the panel voltage is maintained at a fixed open-circuit voltage) to sophisticated microcontroller-type techniques (measuring the input and output power and then correctly adjusting the panel voltage).

The correct choice of MPPT method for charging solutions should be a compromise between cost and efficiency and should depend on the specific application.

Reverse leakage protection

Reverse leakage is the loss of stored charge in a battery and its return to the power supply. Reverse leakage occurs when the battery voltage is higher than the supply. When this happens, the power source becomes the load on the battery and stops charging it. This does not occur when using a wall adapter or USB power source, as the voltage output of both power sources is always above the lithium-ion power supply voltage. When using a solar panel, the voltage of the solar panel falls below the battery voltage in the absence of light. Figure 2A shows a schematic of a USB power charger connected to the battery. When switch S1 is off, the power supply is disconnected from the battery and the battery has no current. When using solar panels, if the same layout is used, the switch body diode turns on if the solar panel voltage drops below the battery voltage. A common solution to this problem is to use back-to-back switches.

Charge termination

Lithium-ion battery charging requires precise current and voltage control to be performed on the battery to ensure that it is fully charged, to prevent shortening the battery life, and to prevent dangerous conditions during charging. The common process of lithium-ion battery charging (see Figure 3) can be divided into the following three stages: pre-voltage, constant current charging, and constant voltage charging.

In the stage of pre-voltage stabilization, the battery is charged with a constant current of 0.1c (usually) so that the battery voltage slowly rises to about 2.5V. This stage is only used for deep discharge batteries. Once the battery voltage rises above ~2.5V, a constant current is used for charging. In the constant current charging stage, charge the battery with 1C constant current (usually) until the battery voltage reaches ~4.2V. Once the battery voltage reaches ~4.2V, a constant voltage of 4.2V is used to charge the battery. At this stage, the current entering the battery needs to be monitored. When the battery current drops to 0.1c, the charging stops. During constant voltage charging, the amount of current entering the battery decreases because the battery impedance increases when the battery is full. Once the current is reduced below 0.1c, the charging source must be completely disconnected from the power supply. If not completely disconnected, there will be a metal lithium electroplating phenomenon, so that the battery becomes unstable, thus a dangerous state. We must terminate the lithium-ion battery charge according to the current entering the power supply to ensure that the battery is just full to its maximum charge.

Chargers charged with solar energy must follow the above charging process. Most problems occur during constant voltage charging, which monitors the battery's current. The amount of current going into the cell may decrease, but not because of the increase in battery power, but because of a decrease in solar panel output due to changes in the light environment. As a result, the battery may never reach its full charge, and the solar panel may always be connected to the battery. To solve this problem, we can use a long time constant timer. At the end of the timer, the solar panel is disconnected from the charger, regardless of battery power, preventing battery damage.

Solar panel crash protection

In some traditional chargers, we know the current and voltage of the power supply in advance. Therefore, the charger circuit is specially designed to operate within the specified range of the power supply. When using solar panel output, current size and open-circuit voltage are dynamic, depending on the surrounding environment. So designing a control loop for a solar charger is a bit more challenging than a wall adapter.

A system that USES solar energy to charge lithium-ion batteries tries to maintain the process without causing the panels to crash unexpectedly. Because the voltage of the solar panel drops sharply, there is no way to get useful electricity from the solar panel. Solar panels are more likely to collapse during constant current charging. At this stage, the solar panels may not be able to supply the current needed to charge the battery. When this happens, the solar panel voltage begins to collapse rapidly. Therefore, the charger must be able to detect a rapid drop in the solar panel voltage and immediately reduce the current from the solar panel to prevent the panel from collapsing.

Solar chargers could provide a mobile, environmentally friendly way to charge lithium-ion batteries. When designing a solar charger, you will encounter many problems that you cannot touch when designing a wall power adapter charger. If designers use their brains, they can design some can use solar energy, USB and wall power adapter input charger, to achieve the perfect lithium-ion battery charging.

Tips for designing solar chargers for lithium-ion batteries

in News

0 comments