The lithium battery is relatively light, easy to carry, and relatively long life. In the case of high temperature, if there is no suitable cooling scheme for the lithium battery of an electric vehicle, the temperature in the battery pack will vary greatly, which will affect the consistency of the single battery and cause a series of subsequent problems.

Advantages of lithium batteries for electric vehicles

- Strong power

- Low volume small

- Low lightweight

- Mileage

- Green environmental protection

- Long life

- Wide operating temperature range

The lithium-ion battery of electric bicycles can operate in the range of -25 to 55 degrees, and its capacity can reach 70% of its capacity, while the lead-acid battery can only operate in the range of 10 to 40 degrees, and cannot operate normally at -25 degrees.

The cooling capacity of lithium battery electric vehicles

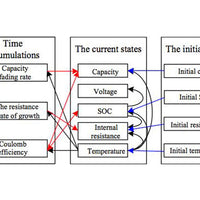

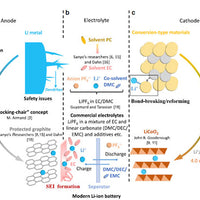

Lithium-ion batteries in charging and discharging process will produce a certain quantity of heat, particularly in the large current charge and discharge process can produce a lot of heat inside the lithium-ion battery, but due to the lithium-ion battery structure thermal conductivity in different directions exist significant differences, in parallel to the direction of the pole piece is a significantly higher thermal conductivity perpendicular to the direction of the pole piece of the thermal conductivity, so different ways of heat dissipation is not only significant difference inefficiency.

The heat dissipation of lithium battery electric vehicles has always been one of the key technologies in the industry. Compared with traditional lead-acid batteries, nickel-cadmium batteries, and nickel-metal hydride batteries, lithium-ion batteries have higher energy density and higher charge and discharge rates. Specially applied in the field of power battery, the road condition is complex and the environment is harsh (especially in the summer with high temperature), the battery heat generation is more intense, which has a more significant impact on the capacity, life span, and especially the safety performance of lithium battery.

To some extent, the safety of the lithium-ion battery problem is, in fact, its thermal dissipation, lithium battery heat production rate is greater than the cooling rate, the battery pack will heat up, once more than the temperature of the battery pack can withstand a tipping point, electrical equipment will be serious safety accidents, so it is very important to li-ion power battery pack heat dissipation problem.

Impress battery has designed the thermal management of lithium battery. The heating and heat dissipation of the battery is very important. The former involves mainly cold start, range, and power, while the latter involves battery system warranty life and vehicle safety.

0 comments