Lithium-ion battery price structure

Lithium battery mainly by the price of batteries, protective plate, and shell parts, at the same time due to the power consumption of the electric appliances and electric current, the size of the material on the connection between the batteries (conventional nickel sheet, forming nickel, copper-nickel composite plate, jumper, etc.) selection will affect the cost of different connectors (such as aviation plugs, from $1 to hundreds of dollars) may also affect the cost is larger, and the different PACK process will also affect the cost.

Factors influencing the price of lithium-ion batteries

I. Cell selection:

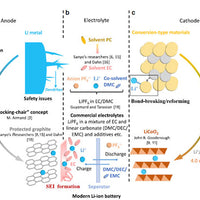

- The selection of different material system cells will affect the price of the whole lithium battery. According to the anode material of lithium-ion batteries is different, there will be a lithium manganese acid (3.6 V), cobalt acid lithium (3.7 V / 3.8 V), nickel, cobalt, manganese acid lithium (commonly known as the NiCoMn, 3.6 V), lithium iron phosphate(LiFePO4, 3.2 V), lithium titanate (2.3 V / 2.4 V), and other material systems of batteries, the batteries of the different material system, its voltage platform, safety coefficient, recycling times, energy density ratio, temperature, etc.

- It is the price of different brands of batteries will also vary widely, the total price gradient can be divided into special batteries (including temperature, super high temperature, super high rate, alien), Japanese (Panasonic, Sanyo, SONY), South Korea (Samsung, LG), domestic (Chinese is divided into a line (Lishen, Bick, BYD, CATL), the second line, or even can be assigned to the five lines, six lines), the material system and different brands of batteries, the price difference will also is very large, and though the quality of the market evolution of each brand batteries (secure, consistency and stability) is proportional to the price.

II. Requirements and design of lithium-ion battery PCM

PCM design can be divided into basic protection, communication

BMS Basic protection:(Hardware type) the basic protection includes overcharge, over-discharge, overcurrent, and short circuit protection, which can be increased according to product requirements

Communication:(Software type) Communication protocols can be divided into I2C, RS485, RS232, CANBUS, HDQ, SMBUS, etc. There is also a simple power display, which can be indicated by the charger and LED.

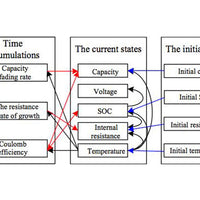

BMS: (Software type) BMS is the Battery Management System first letter abbreviation combination, said that the BATTERY MANAGEMENT SYSTEM, commonly known as the battery nanny or battery housekeeper, mainly to intelligent management and maintenance of each battery unit, prevent the battery has been charged and discharged, extend the battery life, monitoring the state of the battery. Its main functions include real-time monitoring of battery physical parameters; Battery status estimation; Online diagnosis and early warning; Charge, discharge, and precharge control; Balanced management and thermal management. The secondary system is mainly used in electric vehicle batteries.

III. Requirements and design of lithium-ion battery shell

Lithium battery shell design can be divided into PVC heat seal, plastic, metal

PVC heat sealing: The specific packaging form of the outer shell of the battery pack is mainly dependent on the specific needs of customers. PVC heat sealing packaging form is generally applicable to the case of a small number of cell strings and light overall weight (≤2kg). However, for the battery pack with an overall weight ≥ 1kg, it is necessary to add a fixed bracket between the battery cells, and add a glass fiberboard to protect the periphery, and then adopt PVC heat sealing.

Plastic: plastic shell, mainly different battery pack after finalizing the design, involving shell may need to open mold, mold fee is a lot of money, such as the early stage of the development, the product did not finalize the design, can use handmade shell proofing (handmade strength after mold shape is better than material strength), the material and process of the shell (especially the belt is three demands), will also affect the cost.

Metal: The metal shell is the same as the plastic shell, the product is not shaped or the quantity demand is not much, it is recommended to use sheet metal to make the sample, which is mainly to make sample delivery time is short if the batch is large, it is also recommended to make the mold. For the metal shell, waterproof level requirements will greatly affect the cost, there is special material (such as titanium alloy) metal shell requirements, the cost will be higher.

The cost of a lithium battery is mainly composed of the battery cell, PCM, and structural parts. Also, PACK cost, aging cost, and management cost of the enterprise should be added. At the same time, due to the technical difficulty of the product, the purchase amount, defective rate of different requirements, lithium battery prices will be very different!

0 comments