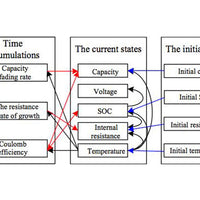

In the process of charging and discharging, the most important link of the lithium battery pack is the equalization link. Lithium battery requires the protection of charging overvoltage, discharging Undervoltage, overcurrent, and short circuit. Because you need to ensure that the lithium battery output and output is reasonable to every battery, the two most common ways of lithium battery balance are energy consumption balance and energy conversion balance.

Some views on lithium battery equilibrium

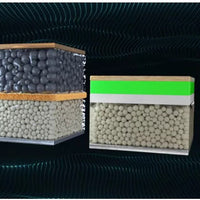

To provide sufficient voltage to the device, lithium battery packs are usually made up of multiple batteries in series, but if the capacity mismatch between lithium batteries can affect the capacity of the entire battery pack. Therefore, we need to balance the mismatched lithium batteries.

1. Lithium battery capacity error is absolute, with the use of lithium battery, this error is expanding. The ex-factory assembly can only delay the time of obvious error of lithium battery. Therefore, the error is absolute, the purpose of the lithium battery protection system and the equilibrium system is only to mitigate the error and avoid the danger of error. Capacity equilibrium is impossible and should not be pursued as the goal of equilibrium.

2. Currently, there is a capacity compensation method, which is to take out some power from high-capacity lithium batteries to compensate for the consumption of low-capacity batteries. This method has no problem in theory, but it is very troublesome in practice, especially it is difficult to achieve high efficiency.

3. Charging voltage balance is necessary, or the lithium battery in the late-charging period will appear as part of the battery undercharging. Some lithium batteries are overcharged, undercharged, which will affect the battery life and lead to danger.

4. Do discharge balance as well as Undervoltage protection, do any single lithium battery Undervoltage protection, to prevent the risk of over-discharge.

Matters needing attention for the equilibrium of lithium battery

It takes a long time to equalize the lithium battery during discharge. Because the discharge speed is related to the load resistance, the equalization efficiency is low. If the equalization is carried out during the discharge and the equalization time is expected to be short, an external power transistor with small on-off resistance is needed. Such transistors are very common, such as MOSFET or FET.

If fast equalization is desired during discharge, the low resistance must be connected in series with the power transistor to reduce the power consumption of the power transistor. Without this current limiting resistor, the transistor would quickly consume lithium battery power.

Measuring lithium battery voltage during charging is not accurate and can cause premature lithium battery equalization. Therefore, the charging must be stopped periodically to measure the battery voltage. Equalization during charging also requires an external power transistor with a low conduction resistance to equalize the battery, which creates the same limitations as equalization during discharge.

Balanced management process design in any kind of li-ion battery system is very important, now balanced management both electric lift trucks in the lithium battery system and new energy automotive lithium-ion battery system cannot leave the balanced management, battery assembly of internal equilibrium management, whether it is conventional lead-acid batteries, or now the very fire of lithium batteries, the stand or fall of performance is not only the performance of the batteries but more depends, on the whole, the balanced management performance of lithium-ion battery pack.

0 comments