PART A-Voltage fault

4-1. The battery voltage is high:

After the battery is fully charged, the voltage of the battery string or strings is high, and the other cells are normal.

The cause of the fault:1. Acquisition error;

2.LMU equalization function is poor or invalid;

3. Cell capacity is low, the voltage rises faster when charging.

Treatment method:

1. The voltage display value of the monomer is higher than the other monomers, and the actual voltage value of the single cell is measured for comparison. If the actual value is lower than the displayed value and is the same as the voltage of other cells, the actual value is the standard for the LMU. The cell voltage is calibrated; if the measured value matches the displayed value, the cell is manually discharged and equalized.

2. Check whether the voltage sampling line is broken or not.

3. Replace the LMU.

4-2. The battery voltage is low:

After the battery is fully charged, the voltage of the battery alone or several cells is low, and the other monomers are normal.

Fault reason:

1. Acquisition error;

2. LMU equalization function is poor or invalid;

3. Cell self-discharge rate is large;

4. Cell capacity is low, the voltage drop is faster when discharging.

Treatment method:

1. The voltage display value of the monomer is lower than that of the other monomers, and the actual voltage value of the single cell is measured for comparison. If the actual value is higher than the display value and is the same as the voltage of other cells, the actual value is the standard for the LMU. The cell voltage is calibrated; if the measured value matches the displayed value, the cell is manually charged and equalized.

2. Check whether the voltage sampling line is broken, virtual connection;

3. Replace the LMU;

4. Replace the faulty battery pack.

4-3. Voltage difference:

Dynamic differential / static differential. When charging, the single-cell voltage quickly jumps to the full-power cut-off voltage; when the throttle is stepped, the cell voltage drops rapidly compared with other strings; when the brake is applied, the cell voltage rises faster than other strings.

Fault reason:

1. Connection battery bronze fastening nut lose;

2. Connection surface has dirt;

3. Battery core self-discharge rate;

4. Battery core connection copper plate open welding (causing the string monomer capacity is low);

5. Individual cells The core leaks.

Treatment method:

1. Tighten the nut;

2. Remove the foreign matter on the connection surface;

3. Charge/discharge the single-string battery;

4. Replace the problem battery pack.

4-4. Voltage jump:

When the vehicle is running or charging, the cell voltage jumps.

Fault reason:

1. The voltage collection line connection point is loose;

2. LUM fault.

Treatment method:

1. Fasten the connection point;

2. Replace the LMU.

PART B-Temperature fault

4-1. Thermal management failure:

1. Heating failure (heating sheet); when the temperature is lower than a certain value, heating does not turn on during charging.

Fault reason:

1. Heating relay or BMU fault;

2. Heater chip or relay power supply circuit is abnormal.

Treatment method:

1. Repair or replace the heating relay or BMU;

2. Check and repair the power supply circuit.

Thermal management failure:

2. Thermal fault (fan); after the temperature is higher than a certain value, the fan is not working.

Fault reason:

1. Fan relay or BMU fault;

2. Fan or relay power supply circuit is abnormal.

Treatment method:

1. Repair or replace the fan relay or BMU failure;

2. Check to repair the power supply circuit is abnormal.

4-2. High temperature:

One or several temperature points in the battery system are high, and the alarm threshold is reached during operation or charging.

Fault reason:

1. Temperature sensor failure;

2. LMU fault;

3. Electrical connection abnormal local heat;

4. Fan is not turned on, heat dissipation is poor;

5. It's close to the heat source such as motor;

6. Overcharge.

Treatment method:

1. Measure the temperature sensor resistance value and display the value. If the actual value is lower than the displayed value and the same as other temperature values, the LMU temperature value is calibrated according to the actual value;

2. Tightening the electrical connection point Clear the connection point foreign matter;

3. Ensure that the fan is turned on;

4. Increase the insulation material to isolate from the heat source;

5. Suspend operation for heat dissipation;

6. Immediately stop charging;

7. Replace the LMU.

4-3. Low temperature:

One or several temperature points in the battery system are low, and the alarm threshold is reached during operation or charging.

The cause of the failure:

1. Temperature sensor failure;

2. LMU failure;

3. Local heating sheet is abnormal.

Treatment method:

1. Measure the resistance value of the temperature sensor and compare it with the displayed value. If the actual value is higher than the displayed value and is the same as other temperature values, the LMU temperature value is calibrated according to the actual value; 2. Check the repair heating piece;

3. Replace the LMU.

4-4. Temperature difference:

Refer to high and low-temperature troubleshooting methods.

The difference in battery heating.

PART C-Charging failure

2-1. DC charging failure:

GB/T27930-2015 charging can not be started, charging jump gun, SOC is not reset after charging.

Cause of issue:

1. Battery failure (voltage, temperature, insulation, etc.)

2. BMU failure (charging module or charging CAN abnormal)

3. Main negative, charging relay is abnormal

4. CC1 ground resistance, CC2 ground voltage abnormality

5. PE abnormal

Approach:

1. Troubleshoot the battery

2. Repair/replacement of failed parts

3. Intercept the charging message to analyze the cause of the failure.

2-2. AC charging failure;

Cause of issue:

1. Battery failure (voltage, temperature, insulation, etc.)

2. BMU failure (charging module or charging CAN abnormal)

3. Main negative, charging relay is abnormal

4. CC earth resistance, CP ground voltage abnormality

5. PE abnormal

Approach:

1. Troubleshoot the battery

2. Repair/replacement of failed parts

3. Intercept the charging message to analyze the cause of the failure.

PART D-Insulation failure

The cause of the malfunction:

The battery box or the plug-in enters the water, the battery core leaks, the environment humidity is high, the insulation is falsely reported, and other high-voltage components (controllers, compressors, etc.) of the vehicle are insulated.

Treatment method:

1. Positive pole to the ground, if there is voltage or insulation resistance value is less than the specified value, the negative circuit is found to be leaking;

2. If the negative pole is grounded, if the voltage or insulation resistance value is less than the specified value, the positive circuit is leaked.

According to the magnitude of the leakage voltage divided by the single string voltage value at this time, the leakage point can be calculated and then analyzed according to different situations.

PART E-Communication fail

LUM communication failure, BMU communication failure;

The whole vehicle is one or several LMU information, or the vehicle does not have BMS information.

Fault reason:

1. LMU/BMU fault;

2. LMU/BMU power supply circuit or communication line contact bad/fault;

3. Signal interference.

Treatment method:

1. Replace the LMU/BMU;

2. Check and repair the power supply circuit/communication line;

3. Check the shielded line to find the source of interference elimination.

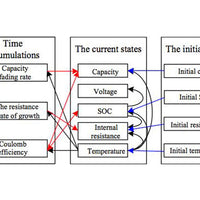

PART F-SOC anomaly

5-1. Inaccurate:

Charged Power ÷ Nominal Capacity = Charged SOC If the "charged SOC" + "remaining SOC" deviates from the actual display value or the actual power does not correspond to the SOC according to the correspondence between the SOC and the OCV, we consider the SOC to be inaccurate.

5-2. No change:

Fault reason:

1. Communication abnormality (data missing);

2. Current abnormality (Hall and its input and output circuit);

3. BMU fault;

4. Other battery alarm.

Treatment:

1. To ensure data integrity;

2. Repair / replace failed parts;

3. Eliminate all battery alarms.

5-3. The decline is fast:

Fault reason:

1. Communication cycle abnormality;

2. Current abnormality (Hall forward current is large, feedback current is small);

3. Cell voltage is low, fast decline;

4. BMU fault;

5. Low temperature.

Processing method:

1. Update the BMU program;

2. Repair/replace the failed component;

5-4. Slow down:

Fault reason:

1. Communication cycle abnormality;

2. Current abnormality (Hall forward current is small, feedback current is large);

3. BMU fault.

Processing method:

1. Update BMU program;

2. Repair/replace failed parts.

5-5. Beating:

Confirm that the program version number is correct.

PART G-Abnormal current

Fault reason:

1. Hall and its input and output circuit;

2. Hall reverse loading;

3. If the BMS demand voltage or current is 0 during DC charging, the charger outputs according to the minimum output capability.

Processing method:

1. Update BMU program;

2. Repair/replace failed parts.

0 comments